Privacy policy/GDPR

To advance the technology of our machines, adapt to market requirements and trends, as well as regulatory requirements, new lithium battery options are now available for FIRSTGREEN machines. Both the Elise and the MiniZ can now be equipped with a selection of LIFEPO lithium batteries, giving our customers a wider selection of options for capacity, weight and lifting power of our machines.

Easier maintenance, simple and quick charging and the elimination of electrolyte management, lithium batteries offer several advantages over their lead-acid counter parts.

Their lightness allows us to decrease the total weight of our machines in some configurations, allowing the machines to be transported easily, while with added or incorporated ballast, the machines still retain their excellent stability, power and centre of gravity.

Supplied by FLASH battery, our lithium battery pack solutions offer a selection of capacity options, from 210Ah in the MiniZ up to 420Ah in the Elise.

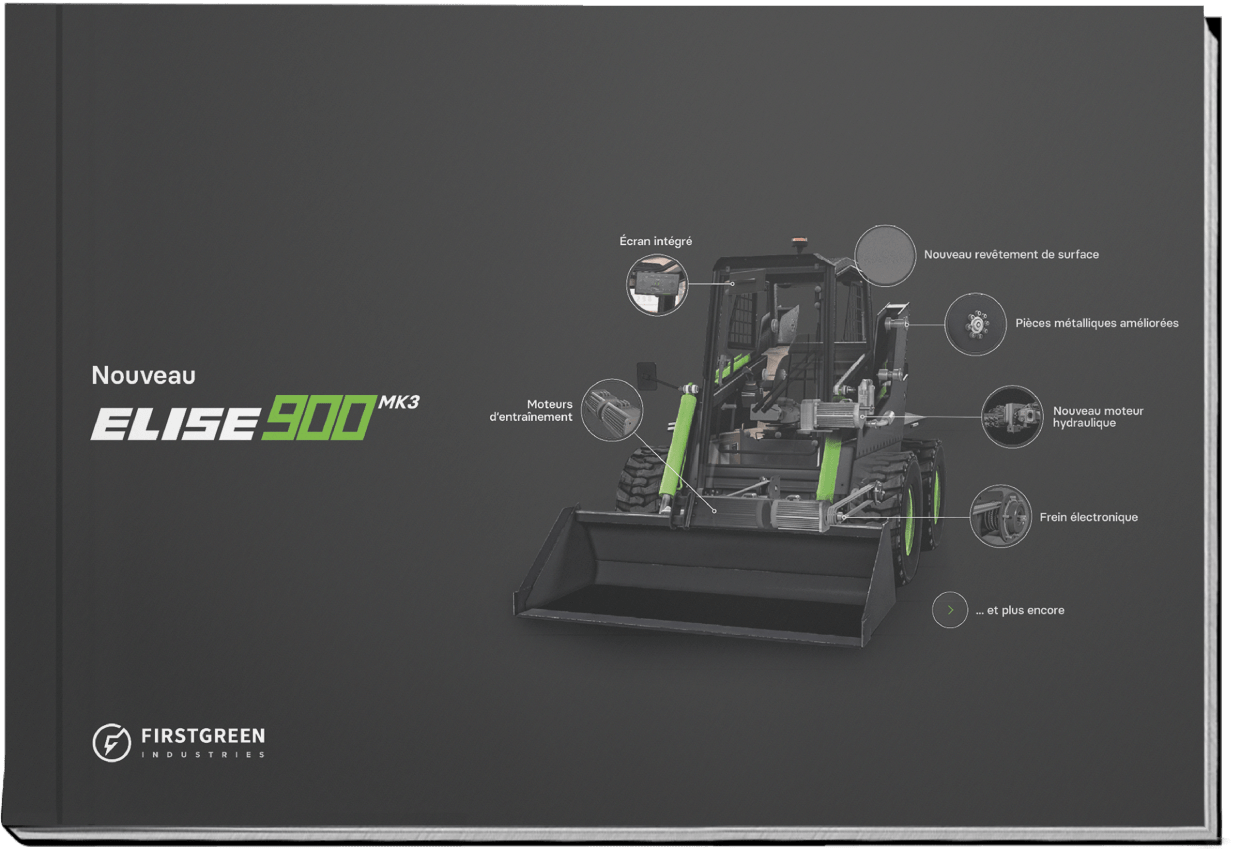

The third generation Elise900 is different at first glance. Thanks to the new surface treatment technology and powder coating, the machine is now more scratch and rust resistant, the smooth surface not only gives it an attractive appearance, but above all improves its washability and makes it easier to maintain, and the precision machined, laser-cut edges make it easier to assemble and repair in the event that a part needs to be replaced.

The control joysticks have been completely replaced. They are now more precise, with less resistance and the possibility of adjusting their parameterization, so it is a more intuitive control system that can be customized according to your own preference. A change in their sensitivity is noticeable by the operator, for example, in the movement of the boom and shovel, which is now more precise and "fits like a glove".

The new CAN joysticks are now connected directly to the CAN-BUS distributor without the use of an analogue converter. The number of wires has therefore dropped to 4 from the previous 25, making the joysticks more reliable and easier to service and replace.

The F2 button now also functions as a switch to set the entire machine to stand-by mode. The operator can now select the travel speed on the left joystick, while the right joystick adjusts the speed of the hydraulics, so the operator does not have to let go of the controls at all. Similarly, the wiper control has been moved to the joystick, with which the automatic wiper is now linked.

The hard-mount display is a new option for the Elise900, an accessory that replaces the mobile phone and acts as the machine's central control panel. Located in the top right corner of the cab, the display offers the possibility of setting three profiles of travel speed and hydraulic settings, each tailored to the needs of different operators or to operate in specific environments.

The display also offers a real-time overview of the machine's tilt, along with sub-menus for error messages and diagnostics.

All new machines come as standard with the wiring harness of the display, which means the screen can then be retrofitted even if it wasn’t originally supplied with the machine.

Hydraulics are an integral part of every skid steer. That’s why we have revised them, and improved the entire system on the new MK3 Elise900.

The new machine now features a more powerful and efficient hydraulic motor, operating at 2700rpm, thanks to which it can now be connected directly to the hydraulic pump for easier maintenance and simplicity.

Replacing the hydraulic brake with the new electromagnetic braking system has allowed us to simplify the whole circuit.

Thanks to the more powerful motor and overall improvements to the system, we have also adjusted the boom and bucket leveling system, which now reacts with greater sensitivity and precision to adjustments of angles and the terrain.

The hydraulic cylinders and piston rods have also been reinforced, to prevent damage from flying debris, and to perform better under severe pressure.

The Elise900 MK3 now features an electromagnetic braking system, which replaces the previously used hydraulic brake. This not only offers greater stability and confidence when stopping on a slope. If the machine needs to be unbraked, for example to pull an inoperable machine, the electromagnetic brake has completely eliminated the process of adjusting the hydraulic pressure, so everything can be done simply by connecting the brakes to a power source.

Thanks to the electromagnetic braking system, the hydraulic circuit, and its maintenance has been greatly simplified.

We have greatly improved the power of the MK3 Elise900, with a new set of electric motors. The new generation now features a new set European electric motors with 40Nm of extra torque, which has improved the overall driving experience, which is now smoother and more responsive, with the power more evenly distributed between forward movement and turning.

Compared to the previous version, the third generation Elise900 runs much smoother, the machine is more refined and comfortable in its movement.

But despite their greater power, the new engines are more efficient and economical, managing the energy resources better, and thanks to their design have improved cooling, reducing the risk of overheating.

In the third-generation machines, the traction motors used for propulsion are different from those used for hydraulics.

The Elise900 MK3 also carries major improivements to the hydraulic cylinders of theboom and hinge. Their new generation is made of higher quality materials, using stronger metals, and a reinforced piston rod. These improvements increase their resistance to damage, benefit their longevity and therefore reduce the need for servicing or replacement.

Nouveau type de chargeurs

Nous avons notre propre équipe de développement et de production tchèque-slovaque et nous assurons tout le développement nous-mêmes. Nous proposons des solutions adaptées au client et aux besoins spécifiques du secteur.